Planning Process

AccuFit will proceduralize and accelerate the number of planned orders you can deliver to production with the assurance that the planned orders are accomplishing

the financial and operational goals of the company.

AccuFit's patented scoring system will prioritize the best fit material in inventory to match to each sales order. The planning function will

be consistent for all your planning engineers and result in high yields and low scrap. Aged remnant inventory will be selected before full

size material is cut.

Financial & Operational Improvement

AccuFit is a financial and operational tool that is specifically designed to:

- Improve your company gross margin by:

- Matching customer orders to raw material inventory better than a human can

- Avoid costly worst case planned orders with low yield results

- Reducing the quantity and average size of remnant material

- Reducing scrap by planning high yield scores

- Targeting obsolete inventory that has been written off by reserves

- Improve your company working capital & cash flow by:

- Targeting aged inventory as a priority in the matching process

- Planning higher utilization of each piece of inventory to avoid remnants and scrap

- Reduce and push out the quantity of new full size material ordered to support

production by consuming remnant and aged inventory first.

New Technology

AccuFit is the only planning and nesting software that:

-

Integrates with your ERP/MRP Software – Oracle, SAP, MAS 90, etc..

-

Generates an image of all your sales orders sorted by cut date

-

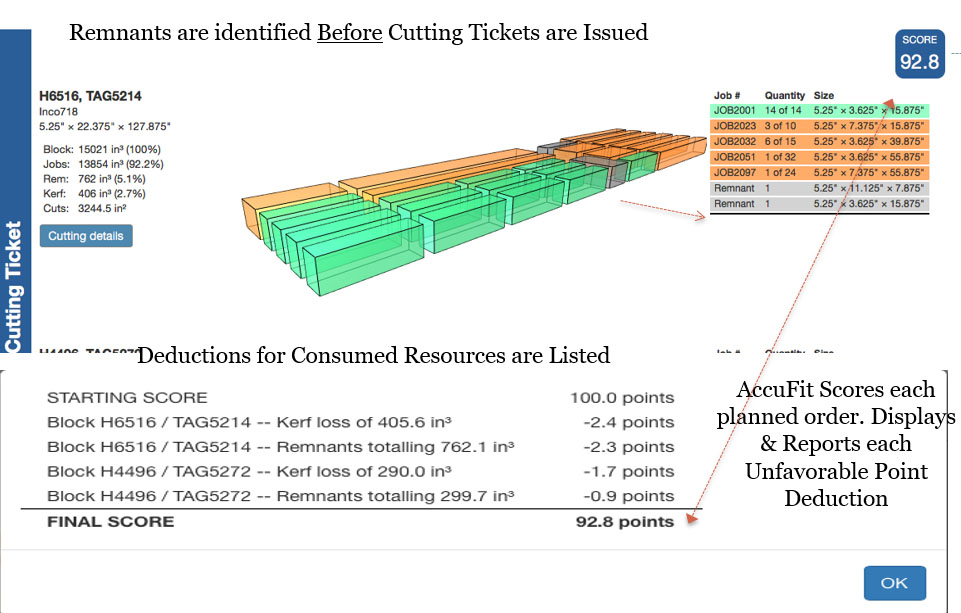

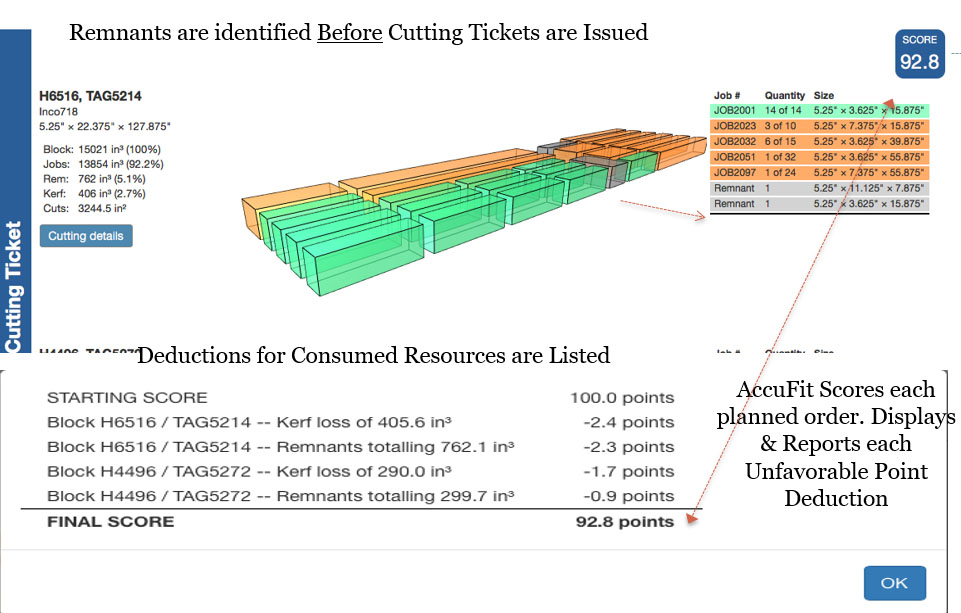

Generates a 3-dimensional illustration of all your inventory that matches each order

-

Calculates a yield score based on a complex algorithm that considers 10 priority factors

-

Generates a 3D image of the material inventory matched to each order and matches

the remnant material to future orders to achieve high material yield and saw efficiency

-

Generates a 3D image of the cutting plan that can be printed or sent electronically to the

saw operators

-

Generates yield reports which demonstrate the amount of remnant and scrap generated from

each plan. This report can be run before the cutting tickets are issue to the floor and low

scored plans can be reviewed and corrected before remnants and scrap are realized

-

Targets aged remant inventory for cutting before full dimension material is cut

-

Targets aged inventory for cutting before new material is cut

-

Only planning software that guarantees lower material COGS, remnant inventory and scrap

Score Reporting

Scoring Algorithm

AccuFit has developed a complex algorithm which considers

the following factors in the calculation of a material plan score:

-

Customer delivery date

-

Material yield percentage

-

Quantity of material heats required to complete customer order

-

Aged remnant inventory

-

Aged inventory – prioritized

-

Reserved inventory – written off or down

-

Material handling – inventory travel to saws and return

-

Remnant dimension and weight (likelihood of scrap or use on future orders)

-

Blade travel – cutting cost

-

Testing cost – destructive and non-destructive

How does AccuFit Improve your Company?

A partnership is agreed to between AccuFit Solutions and your management.

The commitment is to work together to implement AccuFit. The following financial and operational improvements result:

-

Planning department hours are reduced significantly and lead to better planning decisions

-

Bad cutting plans with very low material yield scores are not issued

-

Material match to sales orders leads to higher material utilization results

-

Material handling is reduced as material is completely nested with complete orders

-

Remnant reduction – result of high score yield percentage

-

Scrap reduction from improved nesting and less remnants going to scrap

-

Aged remnant inventory is reduced as it is prioritized for use before new material

-

Aged inventory is reduced as it is prioritized for use before new material

-

3D cutting lists are sent to the saw operators and lead to less scrap

-

AccuFit Reporting = Cost Savings from Analyzing Results

-

Yield Score Report

-

Post Mortem Material Report

-

Remnant Creation from Planning

-

Scrap Creation from Planning